Project: China Resources Breweries Co., Ltd

From 2010, China Resources Breweries Co., Ltd has upgraded all the energy consumption equipments of 96 factories. We tested the electricity and water consumption before upgrade the equipments. Then we record the electricity consumption of Jumsen energy-saving cooling tower. The date is shown as below, with consent of China Resources Breweries Co., Ltd.

Working Condition:

Inlet water temperature = 34℃

Outlet water temperature = 28/27℃

Motor power of cooling tower 11 kw * 2 motors = 22 kw.

Water pump:

Water flow rate = 315 cbm/h

Motor power of of water pump = 45 kw

With a frequency converter of 40HZ. (0~50HZ), to make water flow constant.

Jumsen energy-saving system start working in June 24th, 2013.

- Direct equipment of electricity consumption:

Including a water pump of 45KW, and 2 cooling towers of 11KW, 24 hours running.

|

MONTH |

OLD EQUIPMENT(KW) |

NEW EQUIPMENT (KW) |

|

JUNE |

36954 |

|

|

JULY |

|

31307 |

|

AUGUST |

|

27980 |

- Indirect equipment of electricity consumption: Ammonia refrigerator system ( in July)

|

DECREASED KWH FROM DIRECT EQUIPMENT |

DECREASED KWH FROM INDIRECT EQUIPMENT |

PRODUCTION OF BEAR EACH MONTH |

TOTAL SAVED ELECTRICITY CONSUMPTION |

ELECTRICITY PRICE |

|

0.38 kwh/ 1 ton bear |

0.73 kwh/ 1 ton bear |

15022.5 tons |

16675.0 kwh |

RMB 0.65 |

|

SAVED CHARGE FROM DIRECT EQUIPMENT = 0.38* 15022.5* 0.65 = RMB 3710.6 |

||||

|

SAVED CHARGE FROM INDIRECT EQUIPMENT = 0.73* 15022.5* 0.65 = RMB 7128.2 |

||||

|

TOTAL SAVED ELECTRICITY CHARGE = RMB 10838.8/ month |

||||

After using of energy-saving cooling tower, the electricity consumption of ammonia refrigerator reduce 1.11 KWH/ 1 ton of bear. 0.38KWH saved from direct equipment (water pump & cooling tower), 0.73KWH saved from indirect equipment (ammonia refrigerator)

According to the above data, the cost of Jumsen energy-saving cooling tower would be recovered in 2 years.

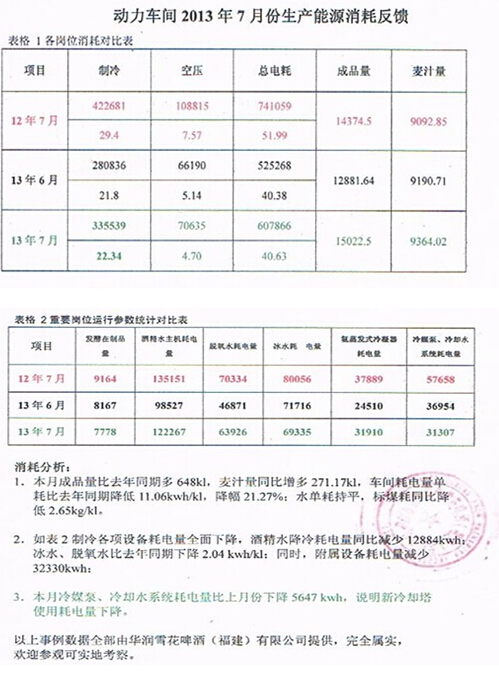

Below is the original document supplied by China Resources Breweries Co., Ltd.